Vi erbjuder ett komplett sortiment av produkter för underhåll, mätning och diagnos av industrimaskiner

Med ledande globala varumärken som Wilcoxon, Sonotec, FLIR och naturligtvis vårt egna varumärke SEMA-TEC, disponerar vi över en imponerande produktportfölj som effektivt löser nästan alla uppgifter inom mätning, analys och diagnos för tillståndsbaserat underhåll, maskindiagnostik och avancerad problemlösning.

På SEMA-TEC erbjuder vi en omfattande palett av produkter, såsom vibrationssensorer, vibrationsmätinstrument, geometriska mätinstrument för kontroll av verktygsmaskiner, axeluppriktningssystem, och ultraljudsmätutrustning för läcksökning och dektektering av elfel. Vårt sortiment omfattar vibrationsgivare av alla typer, accelerometrar, hastighetsgivare, proximity probes och dessutom trådlösa accelerometrar. Vi är stolta över att erbjuda den mest omfattande produktkatalogen och den djupaste kunskapen om tillståndsbaserat underhåll, MASKINHÄLSA – HELT ENKELT™

Produkt- & tjänstekatalog

Produkter

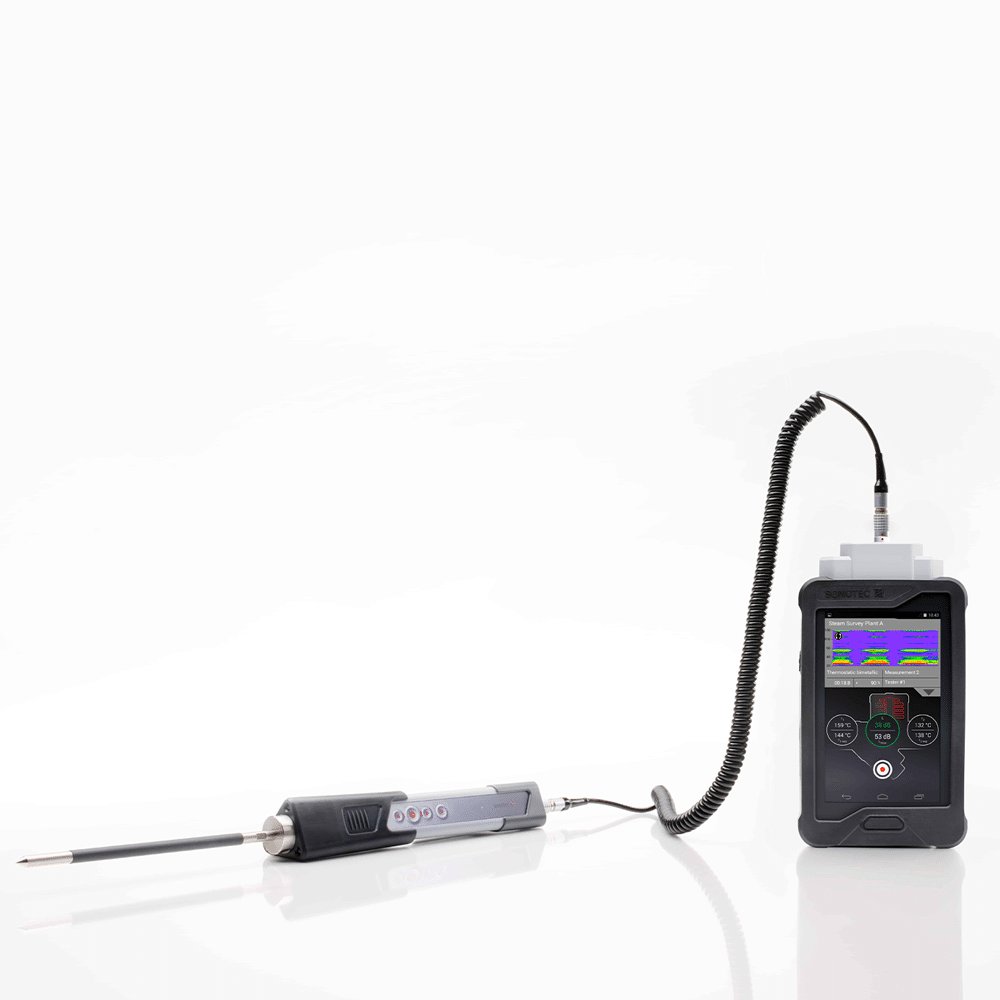

In the age of Industry 4.0 the optimizing processes, increasing operational safety, and improving energy efficiency are becoming more and more significant. Meet the challenges of Maintenance 4.0 with the new SONAPHONE from SONOTEC. The digital ultrasonic testing device combines innovative sensors and software for preventive maintenance that can be operated intuitively and paves the way for new processes for new applications.

The mobile ultrasonic transmitter SONAPHONE T is used for the quick and reliable detection of leaks in windows, doors, cabins, vehicles and containers that have sealing surfaces or profile rubber seals. In connection with an ultrasonic testing device from the SONAPHONE series, efficient tightness testing is possible with very little effort. The simple functional principle does not require extensive training of personnel, nor does it entail any follow-up costs.

The SONASCREEN® 2 acoustic camera enables the precise detection of sound sources in real-time and sets new standards in terms of hardware, performance and usability.

- Reliable detection of leaks and partial discharges, even in noisy industrial environments and with larger sound sources present

- Optimized array with 176 microphones and acoustic imaging at 100 fps for accurate results in real time

- Built-In thermal imaging module (IR) for a more comprehensive diagnosis and analysis of recorded events

Leak Detection Electrical InspectionMicrophones

176 sealed microphones with 200 kHz for capturing the lowest acoustic signals and precise localizing

Speed

Detection of fast-moving sound sources thanks to a high resolution of 100 fps and global shutter

Raw data

In-depth recording and analysis: The only camera that allows further processing of the recorded raw data

Ergonomic design

Handheld device – Low weight, excellent ergonomics and compact size

Wide frequency range

Wide frequency range up to 100 kHz for the detection of audible and ultrasonic signals above typical industrial noise levels

Configurable

8 configurable buttons for an intuitive workflow

Device Modes

4 different modes with preset settings for intuitive operation without extensive training

- EASY – Simplified mode with reduced range of functions for easier operation

- PRO – Expert mode with extended range of functions and adjustable measurement parameters

- LEAKAGE – Optimized mode for quick and easy detection of leaks incl. live loss indicator

- PARTIAL DISCHARGE – Optimized mode for the detection of different types of partial discharges incl. live PRPD display

Industrial grade

IP 54 / protection against water and dust: encapsulated microphones suitable for industrial use

Large screen

7” multi-touch HD display

Vibration

Vi erbjuder ett omfattande och noggrant utvalda utbud av vibrationsmätningsinstrument och -sensorer. Vårt sortiment inkluderar avancerad utrustning för övervakning och diagnostik, samt analysmjukvara med AI stöd. Dessa produkter är utformade för att uppfylla de mest krävande industriella behoven och erbjuder oöverträffad noggrannhet och pålitlighet. Vi engagerar oss i att leverera lösningar som inte bara mäter, men också ger insikter för att optimera och skydda din tillgångar.

Maskingeometri

I vårt sortiment finner du de mest innovativa och avancerade metoderna för att mäta maskingeometri i verktygsmaskiner. Våra verktyg är utformade för att inte bara verifiera maskiners överensstämmelse med specifikationer och ISO-toleranser, men också för effektiv problemlösning. Dessa lösningar representerar en fusion av det senaste inom teknik och smart design, vilket ger en överlägsen precision och användarvänlighet för alla dina mätbehov.

Upprikting

Genom att använda välriktade maskiner minskar du energiförbrukning och vibrationer, vilket bidrar till en förlängd livslängd för dina maskiner. Med hjälp av uppriktninglasrar från globalt ledande tillverkare, kan du effektivt hantera och lösa alla typer av utmaningar relaterade till maskinuppriktning. Dessa högkvalitativa laserverktyg erbjuder precision och pålitlighet, vilket säkerställer optimal prestanda och hållbarhet för dina maskiner.

Ultraljud

Att spara energi genom att upptäcka läckor i tryckluftssystem är avgörande för alla typer av tillverknings- och processanläggningar. Genom ultraljudsinspektioner av elektriska komponenter kan man tidigt upptäcka partiella urladdningar, vilket säkerställer anläggningens tillförlitlighet och säkerhet. Ångfälltestning minskar energikostnader och ökar processstabiliteten. Allt detta är möjligt med ultraljudsprodukter från den världsledande tillverkaren Sonotec.

Sensorer

Vi erbjuder vibrationssensorer och tillbehör av toppkvalitet, för alla typer av applikationer. Bland vårt utbud finns produkter från det välrenommerade varumärket Wilcoxon, känt för sin långa tradition av kvalitet och innovation inom området.

Våra varumärken