RT-300

Connected insights empowering your plant and teams!

RT-300

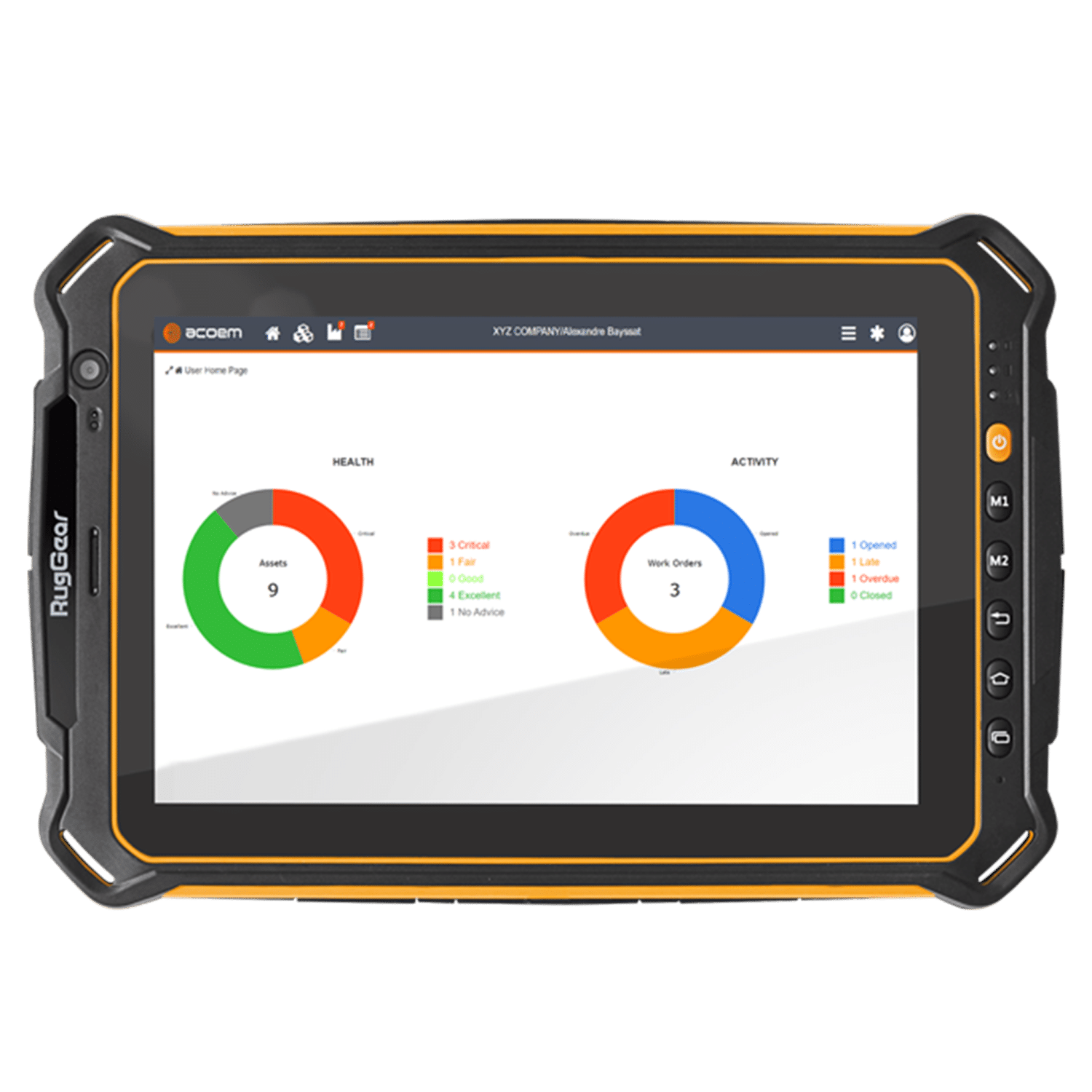

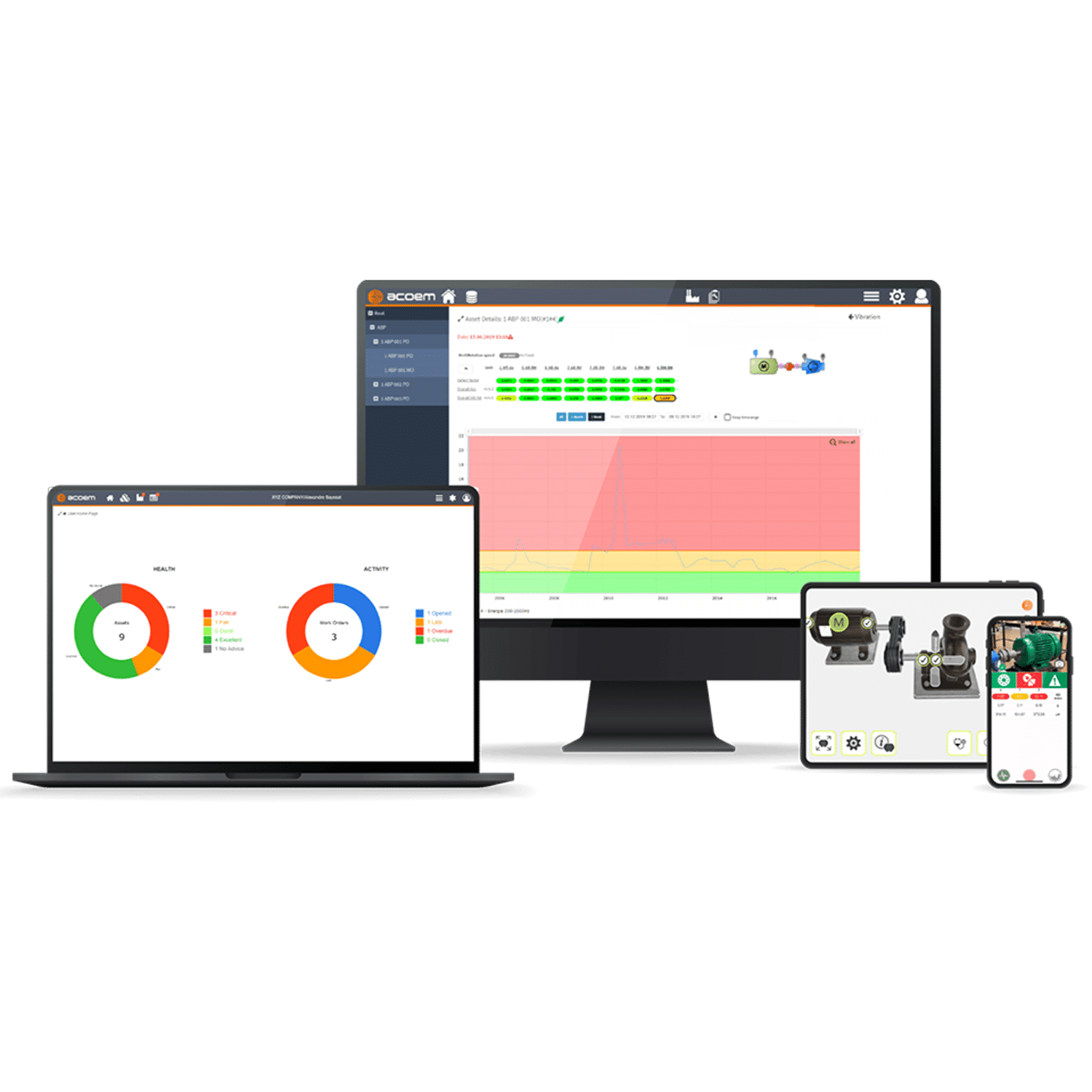

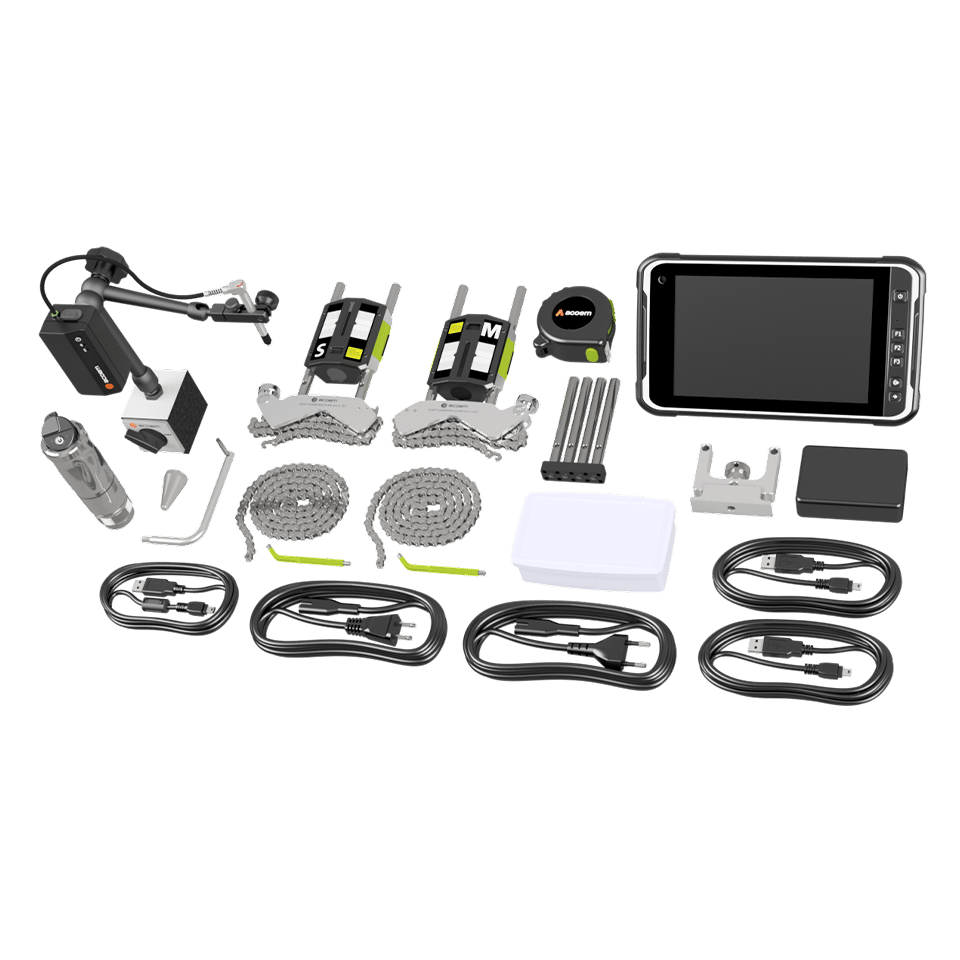

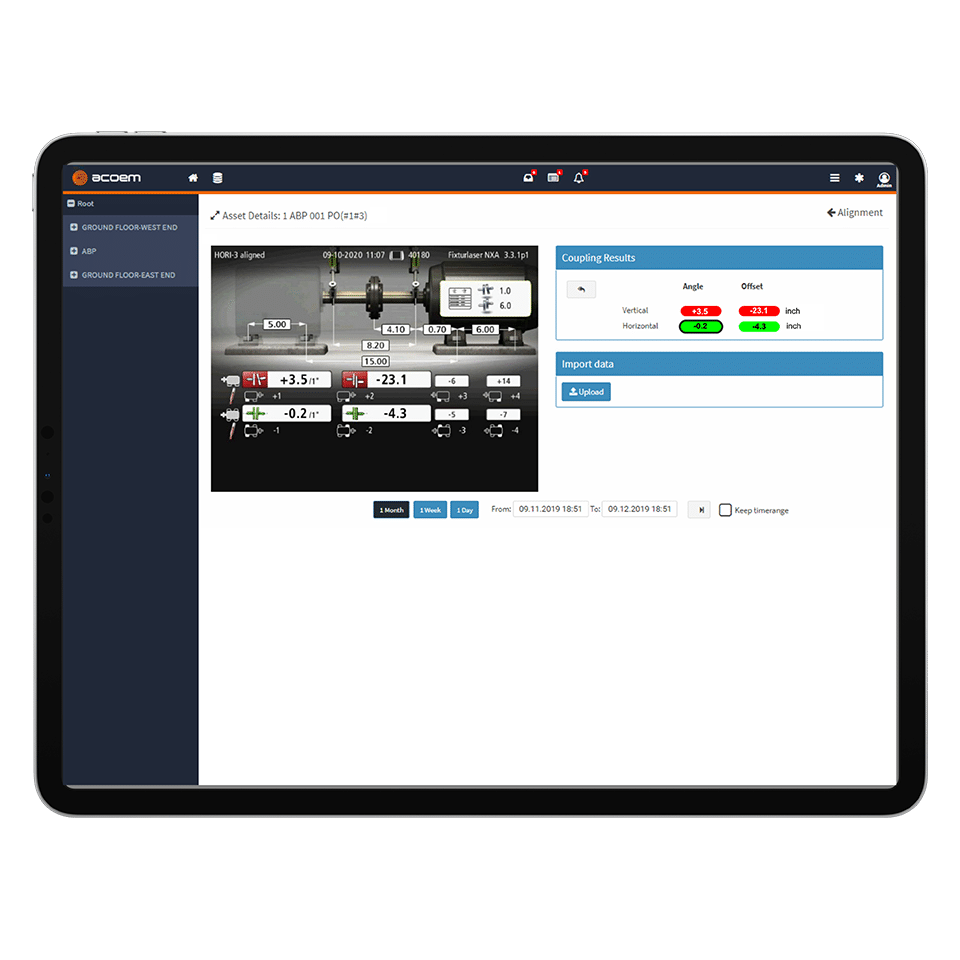

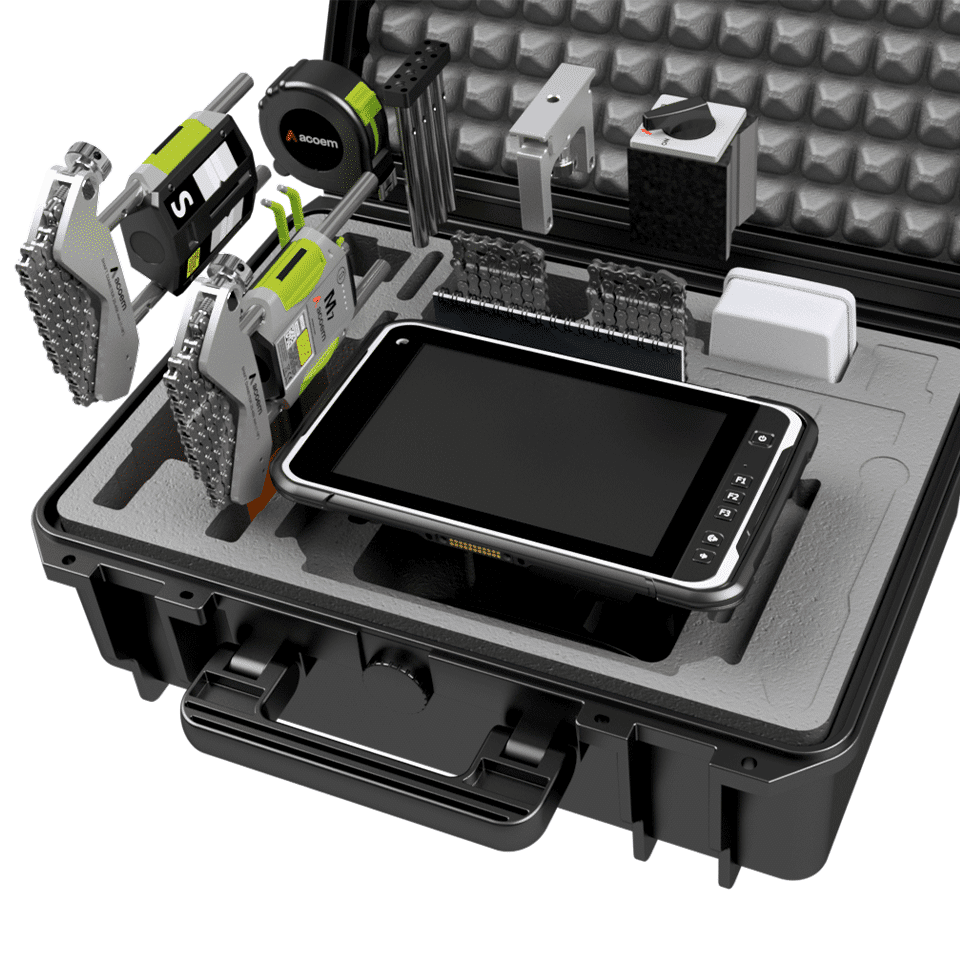

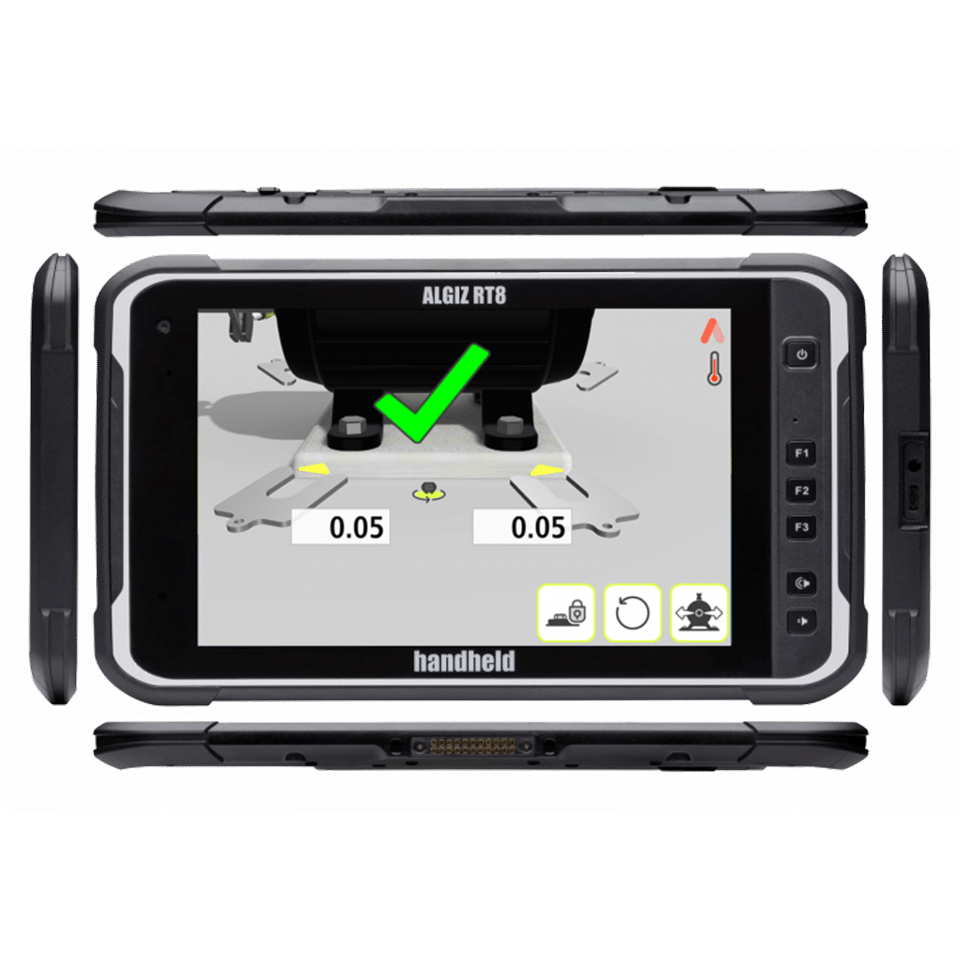

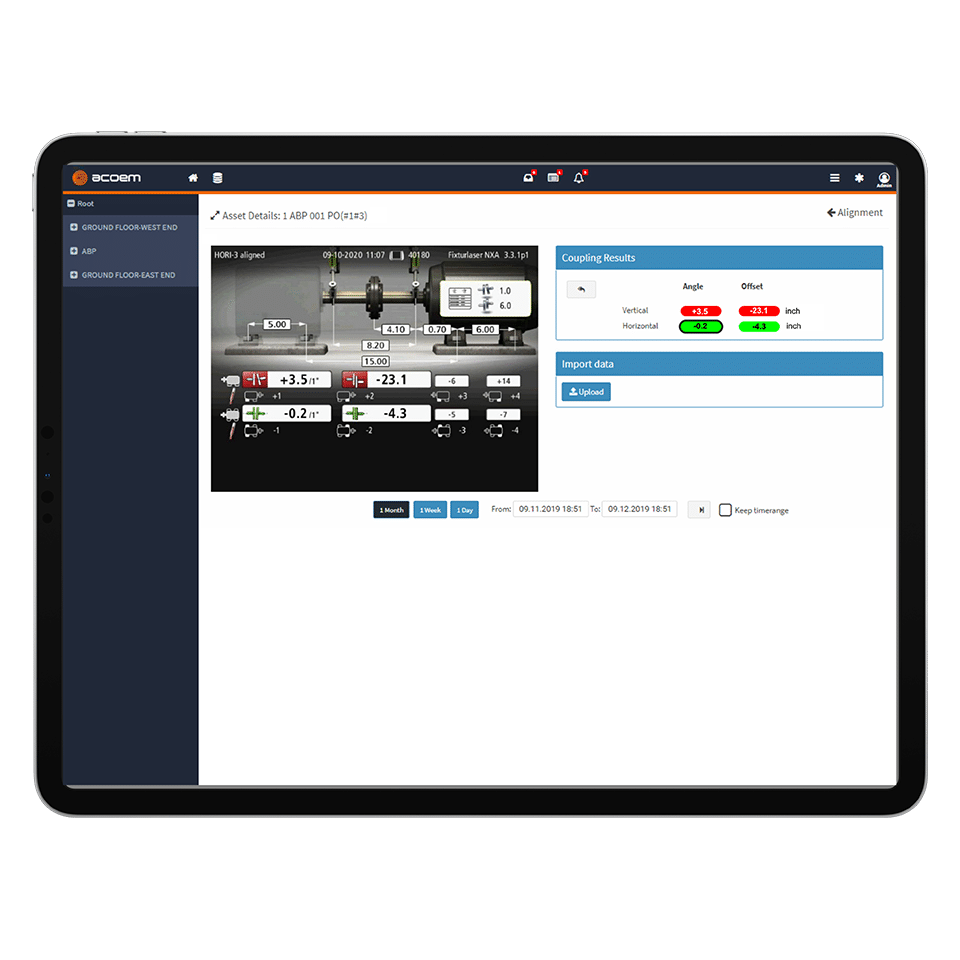

On-the-spot machine diagnostics with a complete precision shaft alignment tool and a cloud connection to save reports and look up historical data, all combined into one tool — the RT-300 is a truly unique reliability tool for the Industry 4.0 mechanic!

Powered by the suite of intuitive applications offered by Acoem, this tool does it all: shaft alignment, vibration analysis, spot inspections on bearings, and safe and reliable measurement with the unique probe for of all pre-alignment checks.

A complete precision shaft alignment tool, on-the-spot machine diagnostics, and a cloud connection for storing reports and reviewing historical data, all combined into one tool, the RT-300 is a unique tool for Industry 4.0 mechanics.

RT-300

On-the-spot machine diagnostics with a complete precision shaft alignment tool and a cloud connection to save reports and look up historical data, all combined into one tool — the RT-300 is a truly unique reliability tool for the Industry 4.0 mechanic!

Powered by the suite of intuitive applications offered by Acoem, this tool does it all: shaft alignment, vibration analysis, spot inspections on bearings, and safe and reliable measurement with the unique probe for of all pre-alignment checks.

A complete precision shaft alignment tool, on-the-spot machine diagnostics, and a cloud connection for storing reports and reviewing historical data, all combined into one tool, the RT-300 is a unique tool for Industry 4.0 mechanics.

Beskrivning

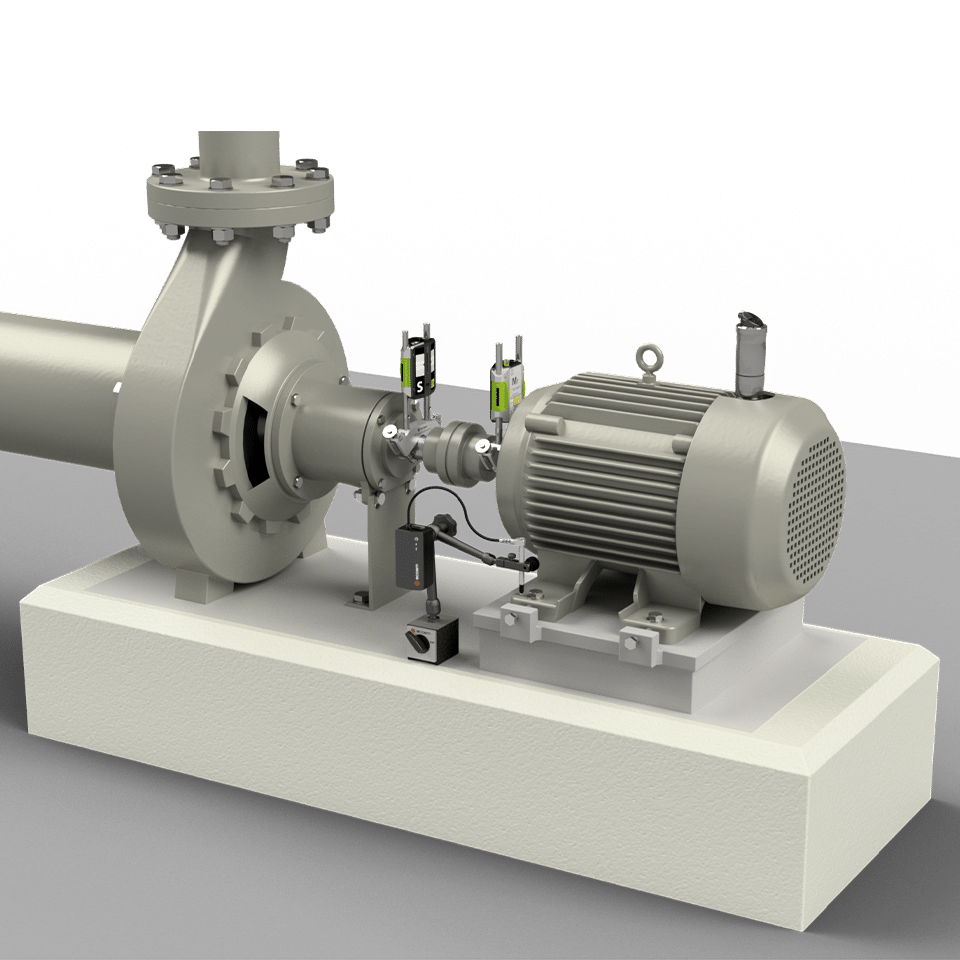

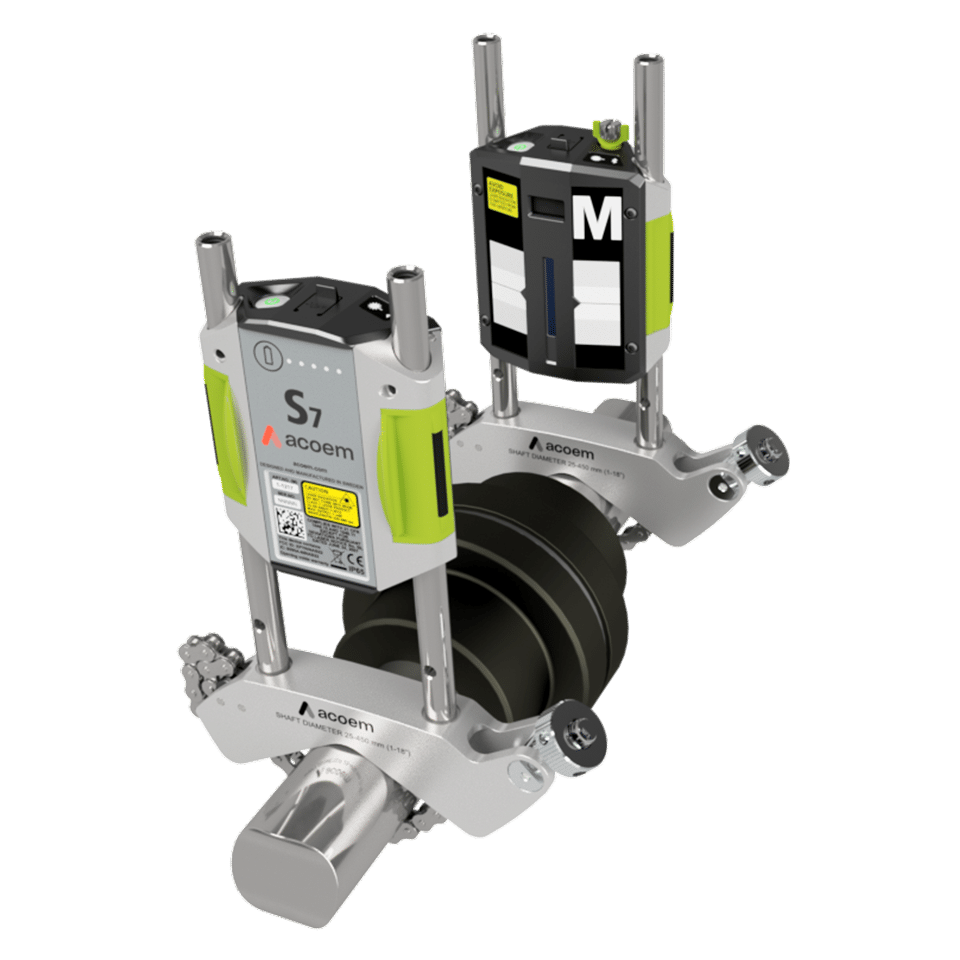

Shaft Alignment

- IP65 certified sensor design that can withstand harsh environments

- 30 mm digital sensor detector + line laser eliminate rough alignment and give you ashort setup time

- Premounted fixtures and small sensors provide quick setup also on machines with limited space

No doubts, no guessing games, thanks to the industry-first use of technologies of two smart sensors with visible laser beams and inclinometers monitoring both shaft positions simultaneously.

Did you interrupt the laser beam? Or move the machine’s position out of the detector range? Not a problem, our smart sensors will resume with an updated machine position and always deliver live values to you.

Pre-Alignment

The Run-Out probe – a smart displacement probe for safe and reliable measurement of axial and radial runout

- High Precision & Wireless probe that measures directly on the machine foot.

- LVDT sensor with ± 2,5 mm measurement range and high precision (within 0.005 mm).

The Runout probe performs a multitude of applications that will improve your machines’ health and lifetime, eg:

- Axial and radial runout checks on flanges and shafts through measuring eccentric or skewed mounting of coupling hubs, and/or checking for bent shafts – Run-Out

- Checking movements directly on machine feet, ie soft foot – True SoftCheck, an industry-first function

- Checking bearing clearances – LiftCheck

- Checking movements due to pipe strain

- Thermal growth measurements on machine casings

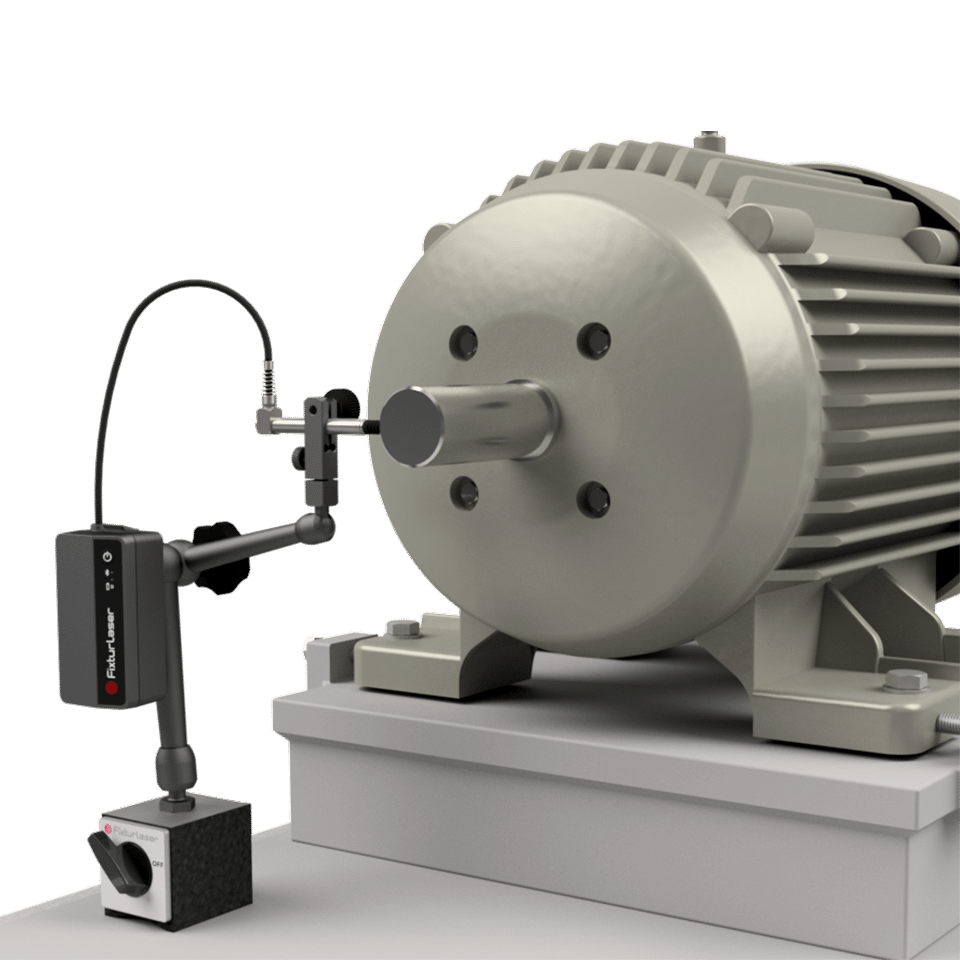

Machine Defender

Machine Defender’s unique automatic machine diagnostic Accurex™ is built into the system. The patented machine diagnostics feature provides unbeatable fast, relevant and reliable results for a wide range of machine problems such as unbalance, alignment errors, cavitation, structural resonances, bearing problems, and more. Machine Defender’s machine diagnostic function differs from all other systems.

- Patented Wireless Triaxial Measurement

- Detects faults on machines more accurately and reliably than any previous automatic diagnostic tool thanks to the patented Accurex™ software.