NXA Pro

It is a shaft alignment revolution

NXA Pro

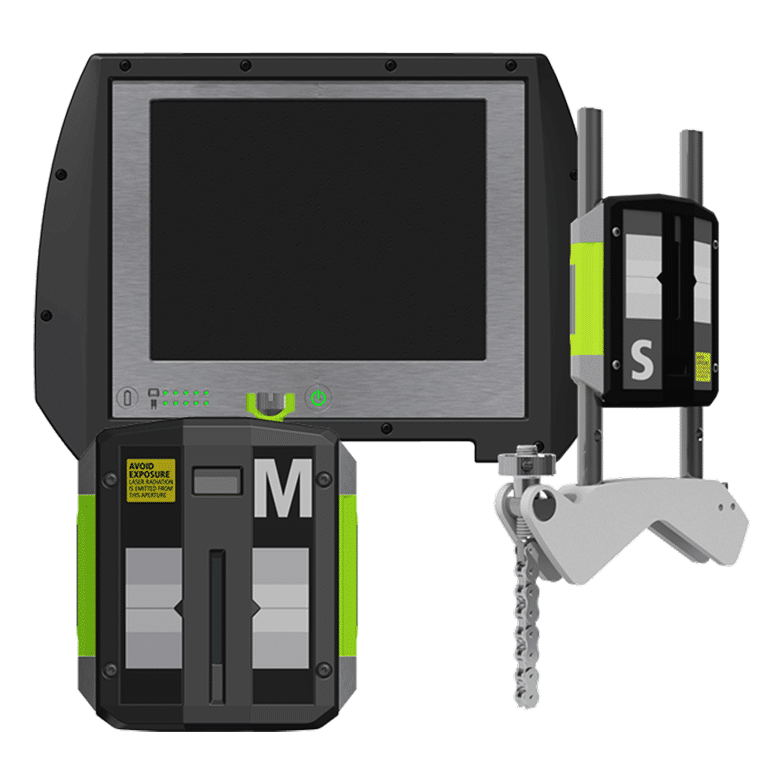

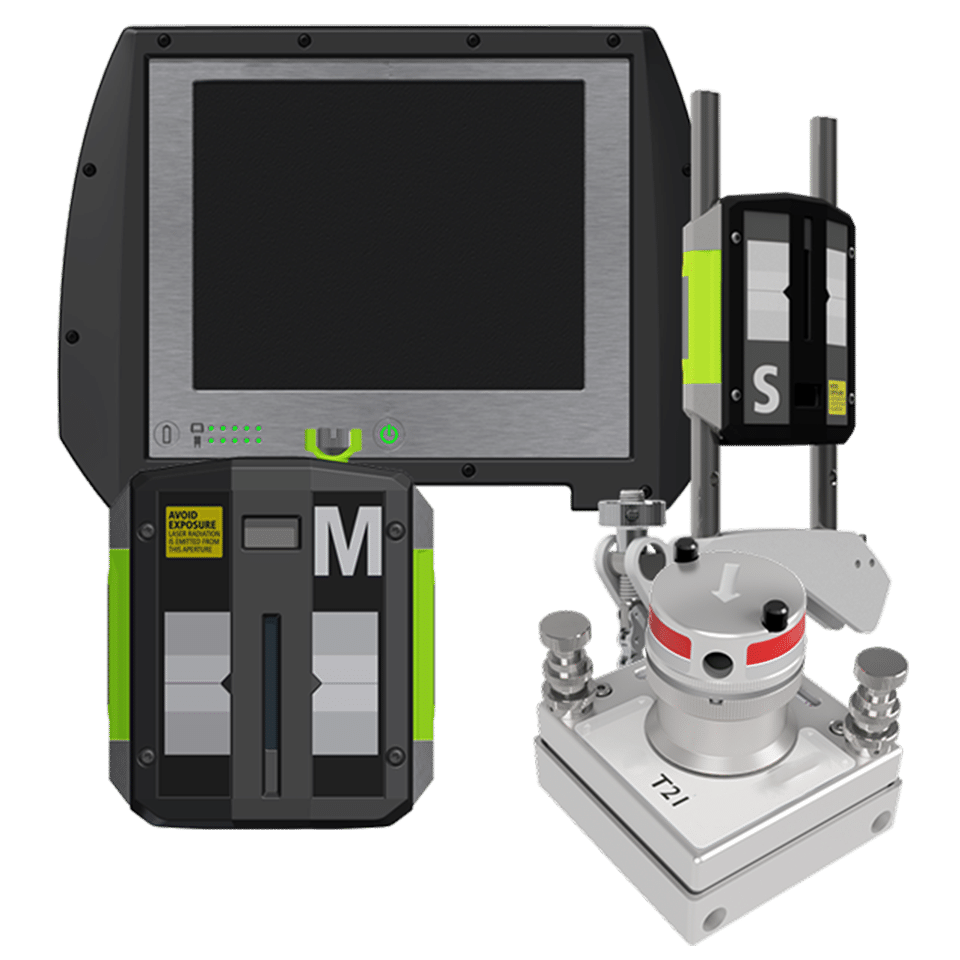

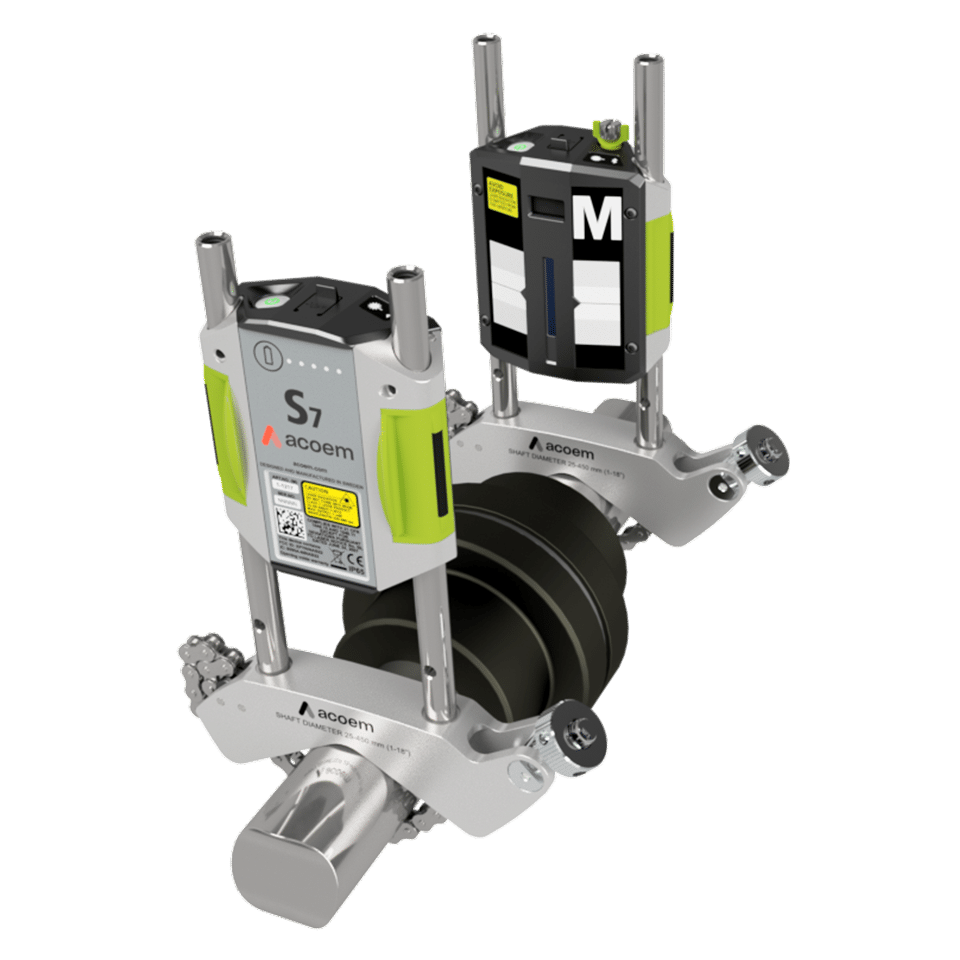

A revolution in shaft alignment as well as usability with the new NXA Pro – a shaft alignment system based on digital laser!

NXA Pro seeks to provide the user with quick and easy operation, as well as access to advanced functions and capabilities, such as OmniView™ and VertiZontal Moves™, and probably the best battery and charging features on the market.

NXA Pro

A revolution in shaft alignment as well as usability with the new NXA Pro – a shaft alignment system based on digital laser!

NXA Pro seeks to provide the user with quick and easy operation, as well as access to advanced functions and capabilities, such as OmniView™ and VertiZontal Moves™, and probably the best battery and charging features on the market.

Beskrivning

OmniView™

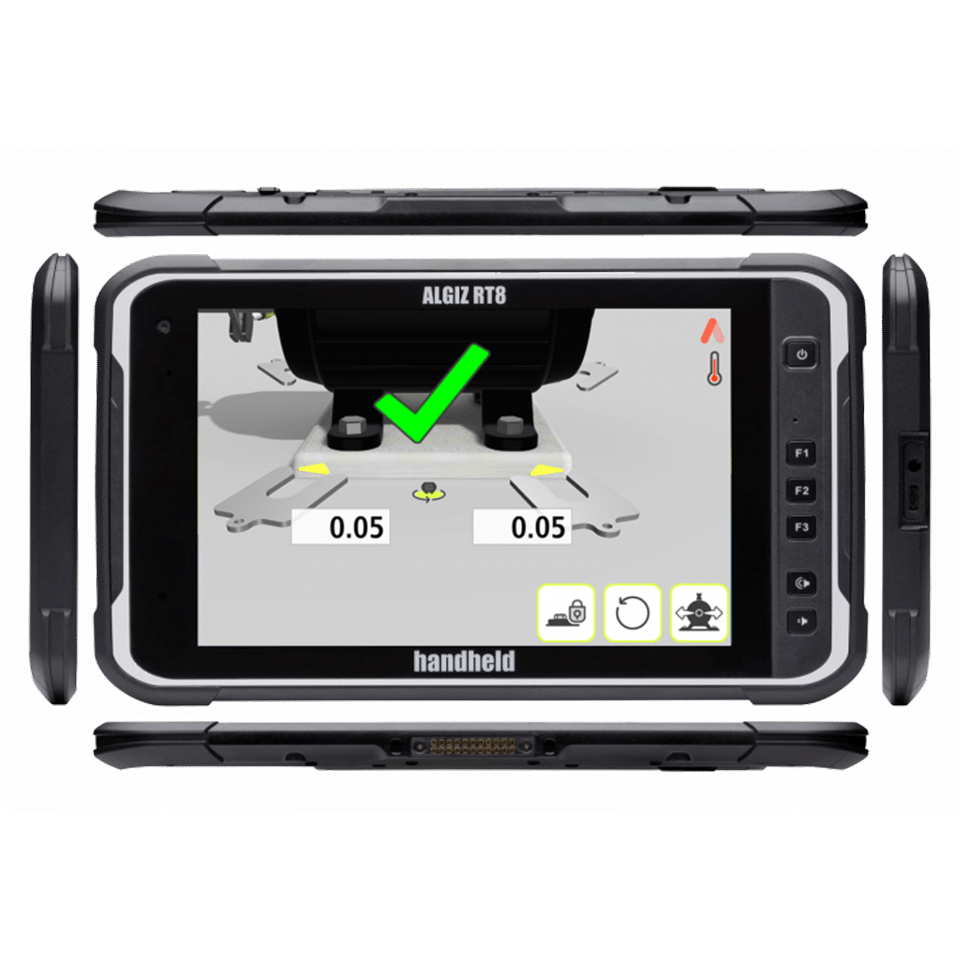

The graphical user interface is shown off on a 6,5” transreflective display screen with icons and symbols to guide you, in other words, no text is involved. The adaptive user interface will guide you throughout the measurement and alignment process.

We have fitted the NXA Pro with gyros and can, therefore, adapt the screen view from the same side that the user is positioned – our OmniView™ function, i.e. the system knows where it is in relation to the machine.

VertiZontal Moves™

The adaptive user interface will guide you throughout the measurement and alignment process. We are especially proud of the function – VertiZontal Moves™ – where you only have to measure once before making the required vertical and horizontal adjustments. Quite a time conserver in a time-strained maintenance world!

Power management system

The NXA Pro has a power management system that will make your life so much easier! The display unit has a 10 hour continuous battery operating time, and should the need arise during an alignment job; the display unit can be express charged to an 80% capacity in one hour. The sensor units will last for 24 hours minimum thanks to the long-life batteries.

Time-saving technology

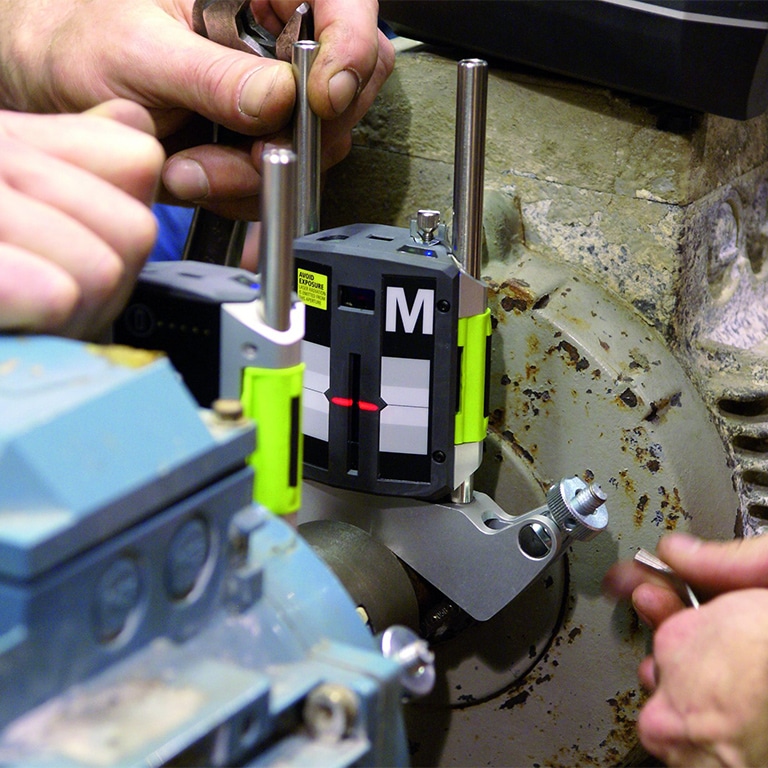

The NXA Pro’s sensor units have graduated to the 2nd generation sensor. This sensor version improves the tolerance for detrimental external factors, such as vibrations and ambient light, and delivers the most accurate and precise measurement values compared to any other system. Measurement values are automatically registered throughout the entire measurement process. We have integrated line laser with the sensor and this combination virtually eliminates rough alignment, a huge time saver.

Very compact, only 33,5 mm in width, the sensor units will fit in the tightest spots. The sensor units contain long-life batteries, Bluetooth communication, and gyroscopes. The gyroscopes make it possible to measure according to the Tripoint Method in the vertical shaft alignment application, something that no other shaft alignment instrument is capable of!

Ytterligare information

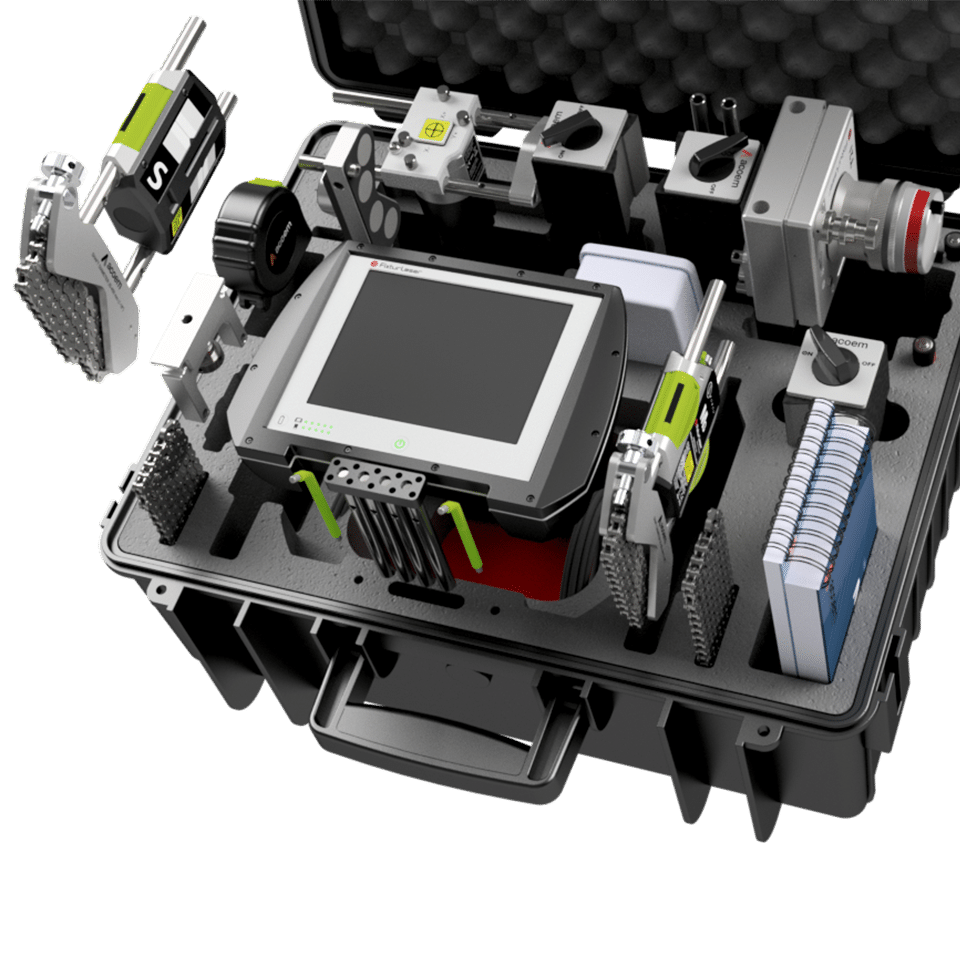

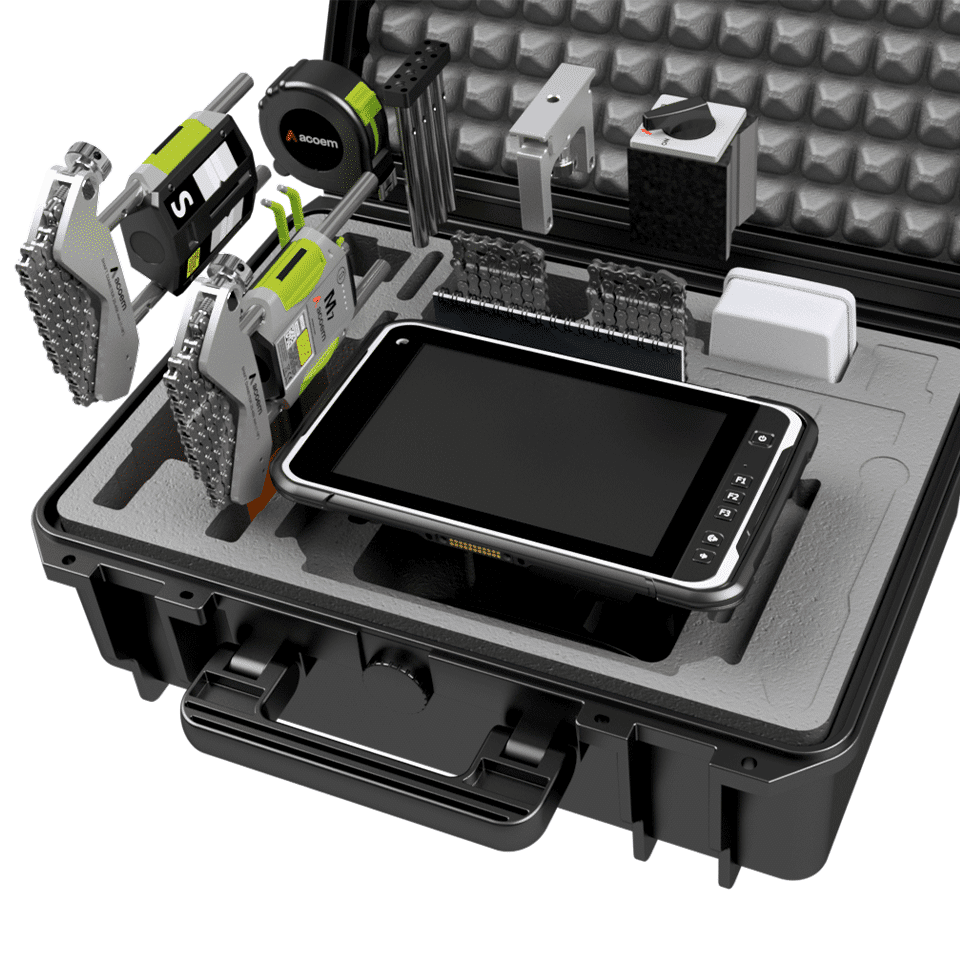

| What's in the case? | Display unit |

|---|