MEAX MT20

Effective horizontal lathes on turning centres

MEAX MT20

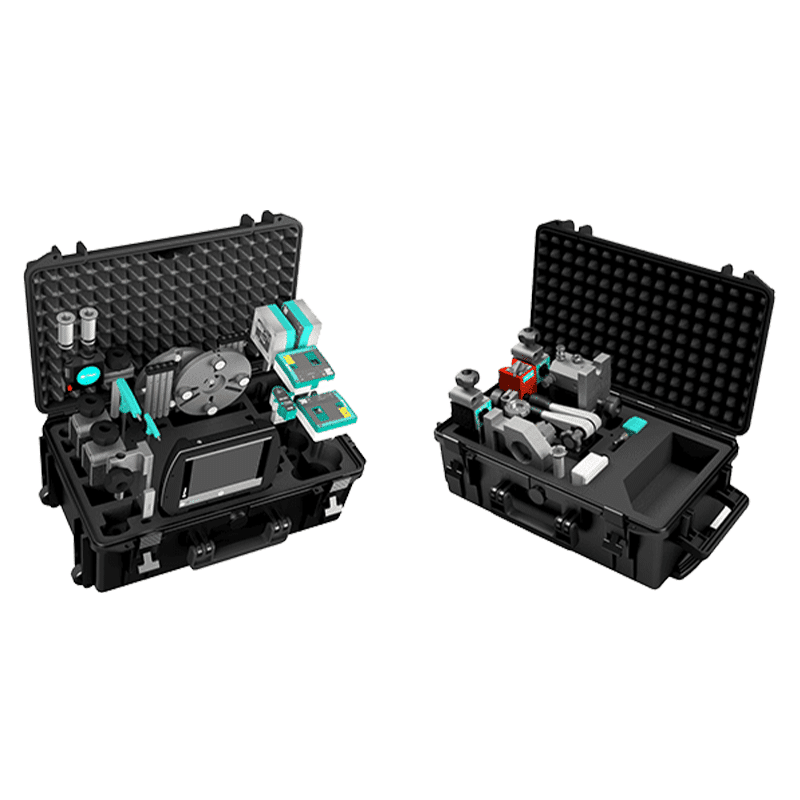

The tailored software guides you through the measurements, allowing MEAX MT20 to be used by anyone. The measurements are made by connecting the wireless sensors to the MEAX display unit, which displays the result directly. The measurements can be saved and then transferred to create additional reports. The Meax MT20 system comes in a small robust case which is easy to carry around with you.

![]()

MEAX MT20

The tailored software guides you through the measurements, allowing MEAX MT20 to be used by anyone. The measurements are made by connecting the wireless sensors to the MEAX display unit, which displays the result directly. The measurements can be saved and then transferred to create additional reports. The Meax MT20 system comes in a small robust case which is easy to carry around with you.

![]()

Beskrivning

Strevel

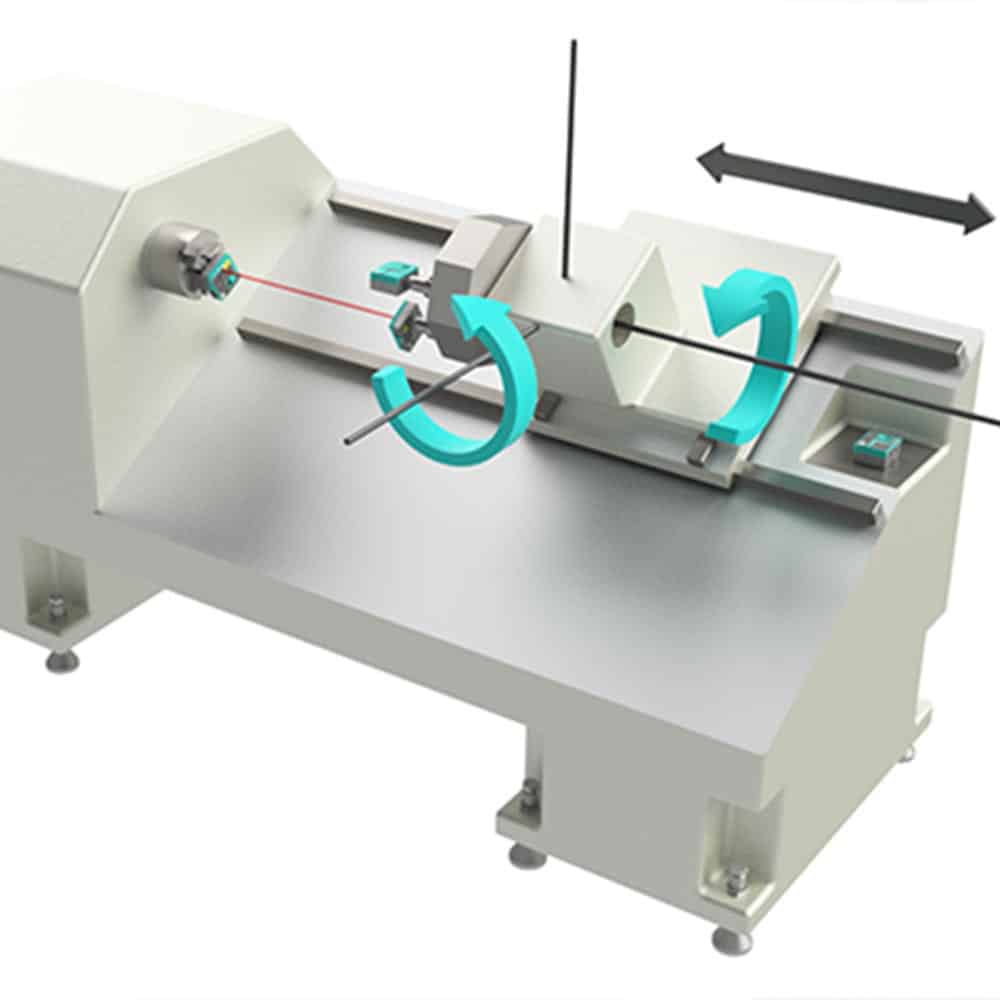

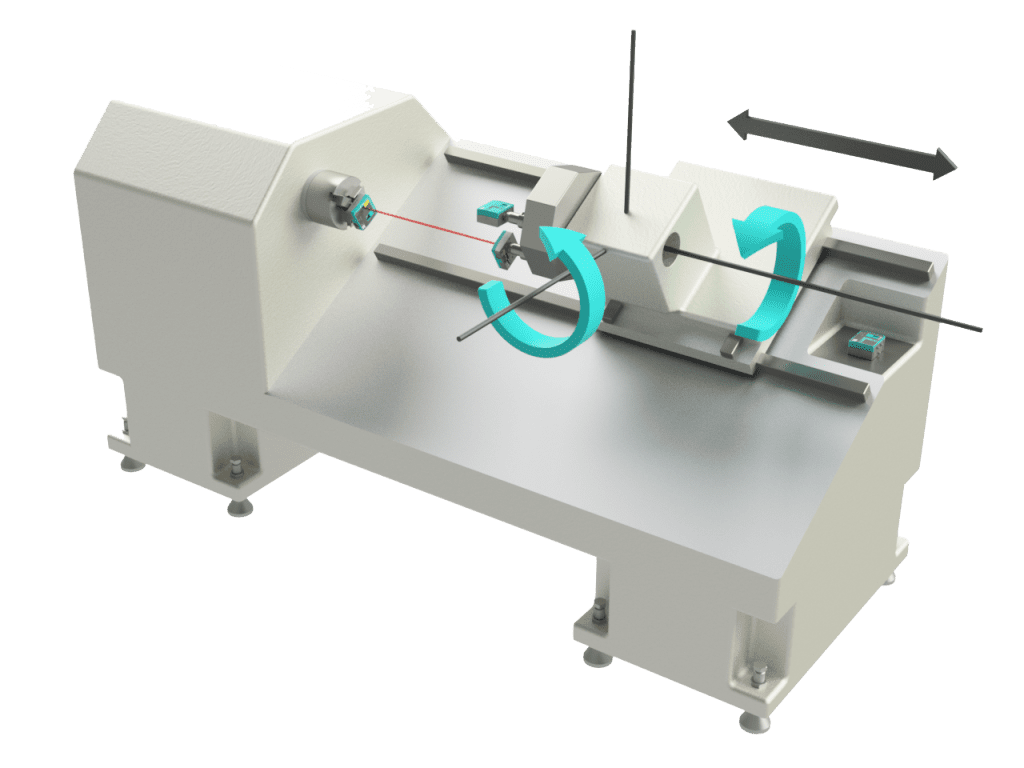

To check that the machine’s movements run straight without any pitch and roll, a solution with multiple sensors is required.

The MEAX LR sensor is positioned on the machine bed and the LM sensor is fitted to the tool holder using the attachment supplied. The SR sensor is mounted in the main spindle and the MEAX SM sensor in the tool holder. The result is displayed as a set of measured points along the length of the movement.

This way MEAX MT20 checks the straightness of the machine’s movement, at the same time as measuring the angular deviation of the movement in relation to the machine bed. The result is displayed in both graphic and text form, and can easily be exported via USB.

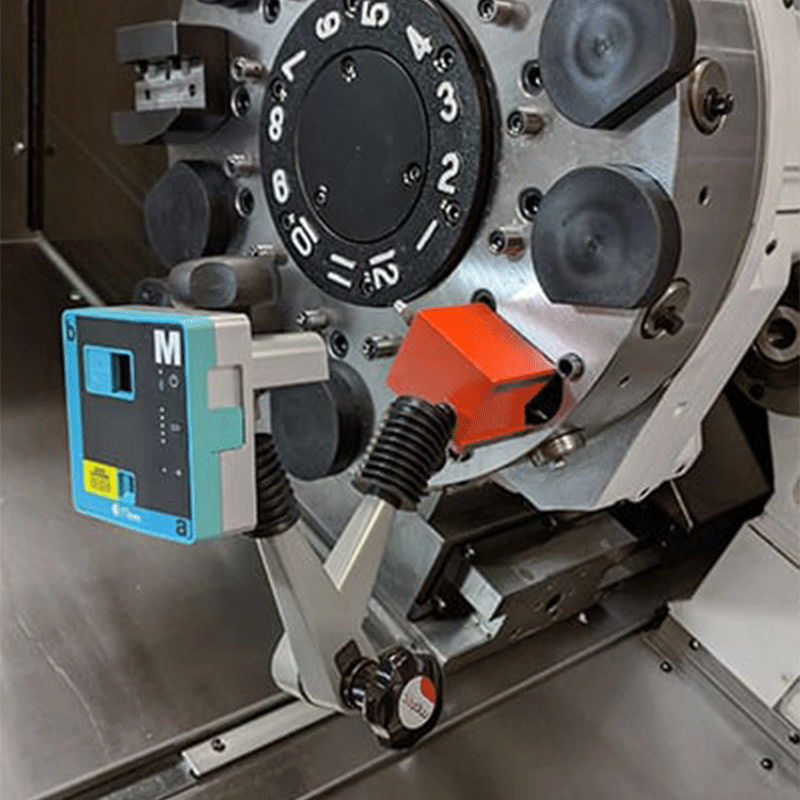

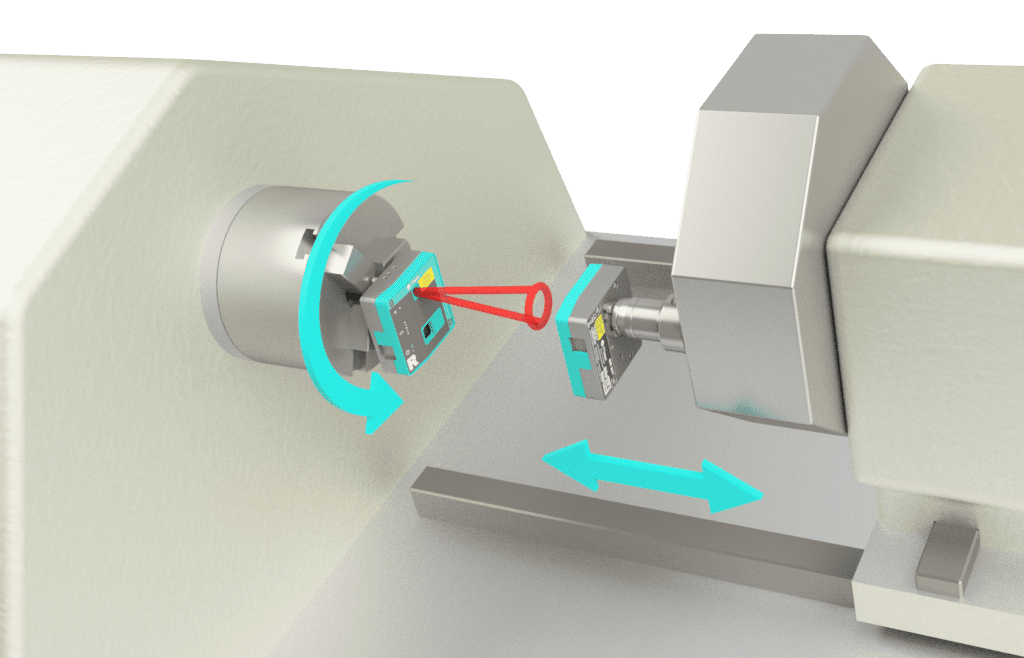

Spindle direction

Because deviations in spindle direction impact on the machined part, it is important that this can be easily measured. You check the deviation via four measured points in two positions along the Z-axis. By rotating the laser in the spindle and moving the MEAX SM sensor along the Z axis, you obtain results for parallel alignment between the rotational axis of the spindle to the 2-axis movement. The results are displayed in graphic form in two directions: square and parallel to the machine bed and in parallel with it.

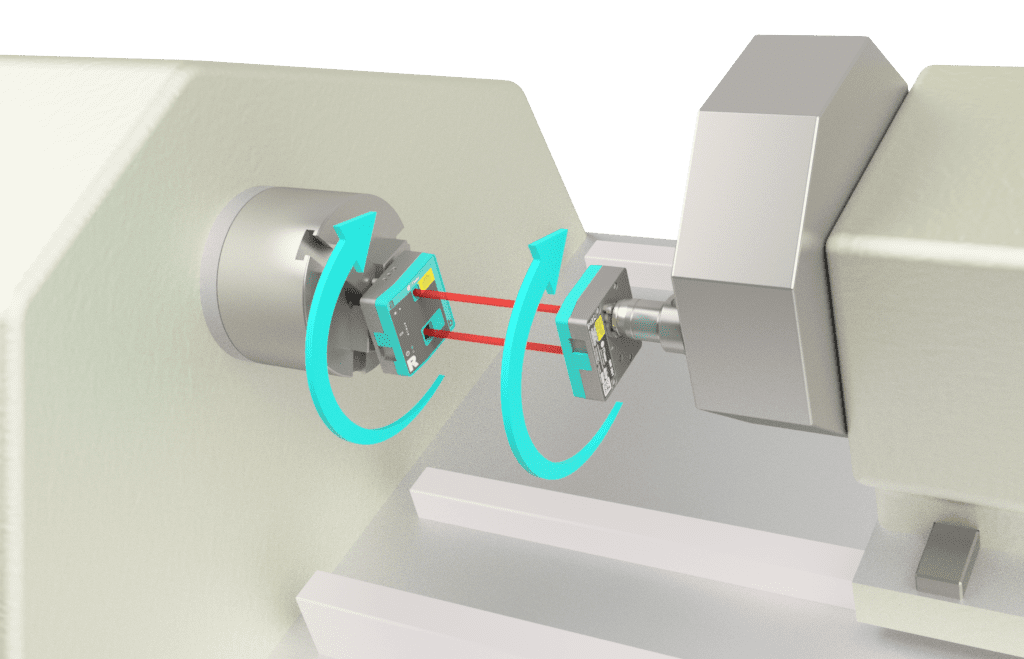

Coaxiality

Using the MEAX SR and SM sensors, you can measure alignment

between the main spindle and the tool holder to quickly set a zero point in the tool holder.

The measuring instrument guides you through the entire measuring process. The software shows you how to take measurements in four rotation positions and then calculates a result that shows the angular error and center deviation between the spindle and tool holder. Adjustments can then be made in the live function unique to MEAX.

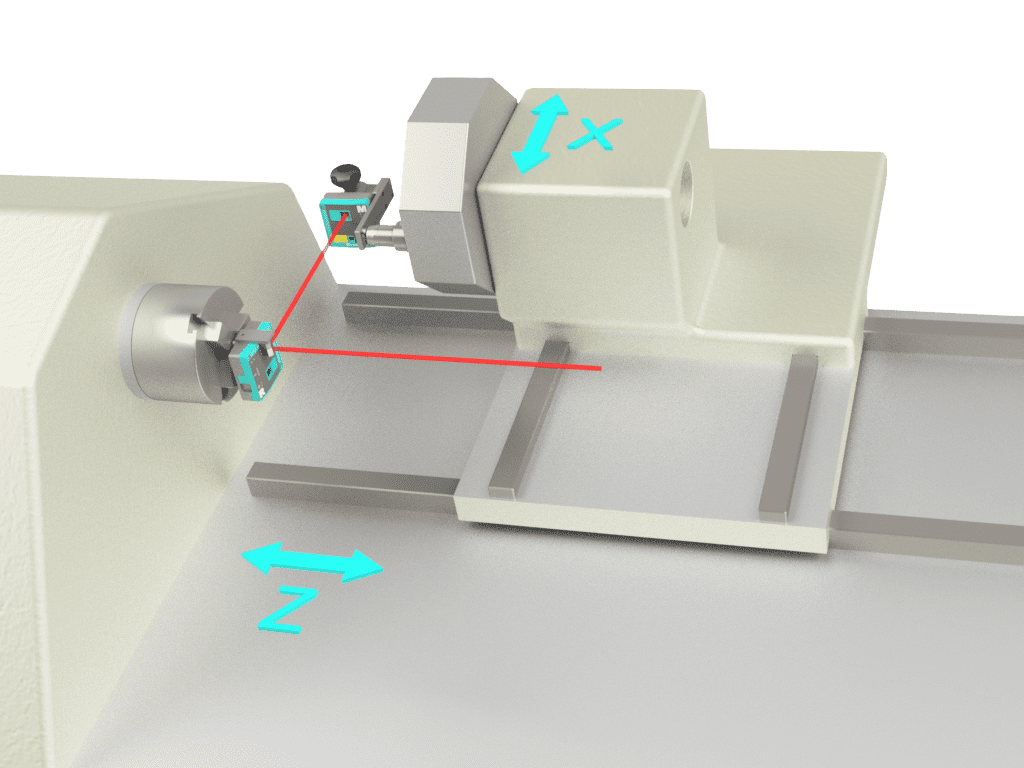

Squareness

By fitting a prism to MEAX SR, you can measure whether the machine’s movements are square with each other. The measurement is performed in two steps: first by measuring the X-axis and then the Z-axis. The software helps you perform the measurement; you will see the angle deviation directly. The customized fixture makes it easy to fit the sensors, thus ensuring a correct result.