Meax® Level Single

Unique 2-axis high precision inclination sensor for machine leveling

Meax® Level Single

Meax® Level is a unique 2-axis high precision inclination sensor with a large measuring range (± 100 mm/m) with the same accuracy (± 5 µm/m).

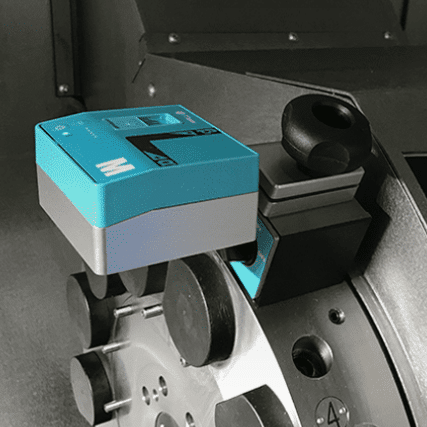

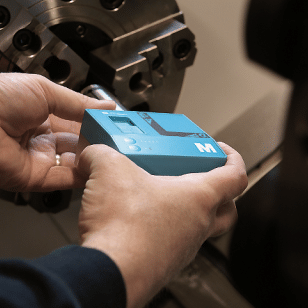

The MEAX Level Single uses one 2 axes-sensor for different measurement tasks when checking the geometry status of machine tools. It uses the readings from the 2-axes level sensor and connects to any mobile device which displays the measuring results in the Meax Level App.

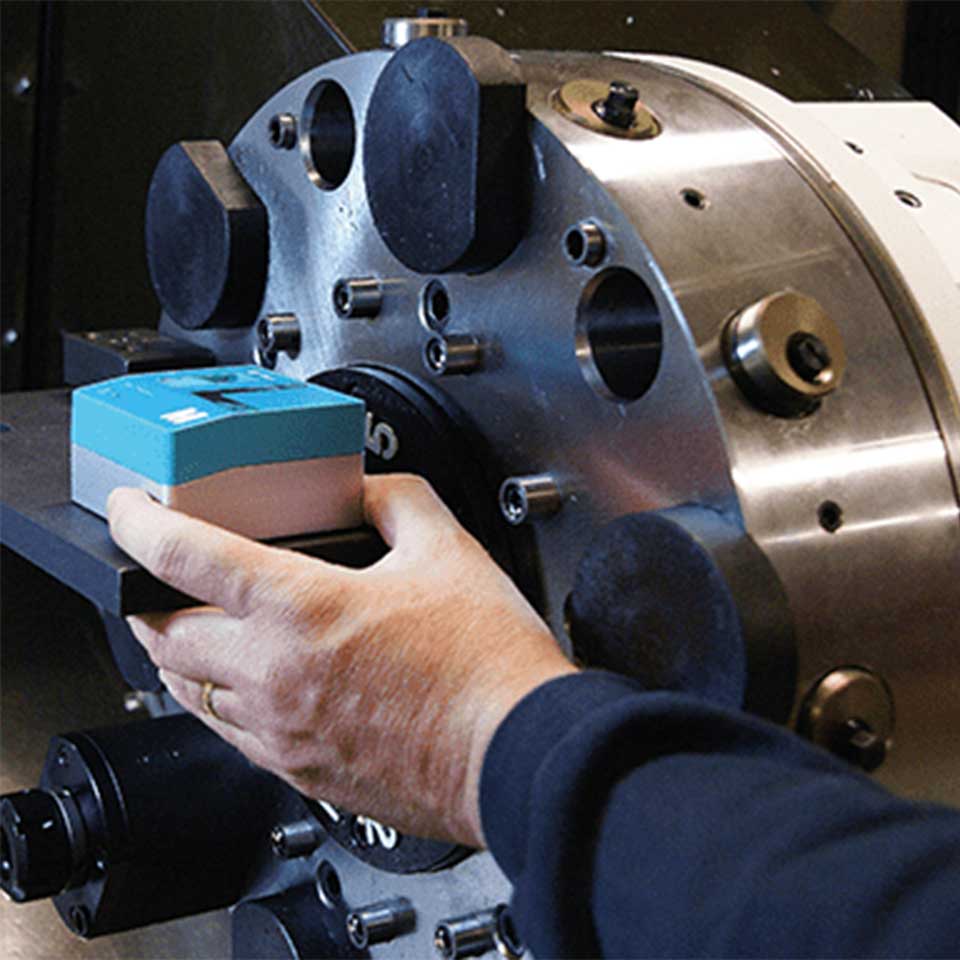

With Meax Level Single it is possible to measure an object’s inclination towards gravity (leveling) or to measure an object’s relative angular deviation (roll/pitch) during machine axes movement. The sensor can also be used to monitor any angular movements over time.

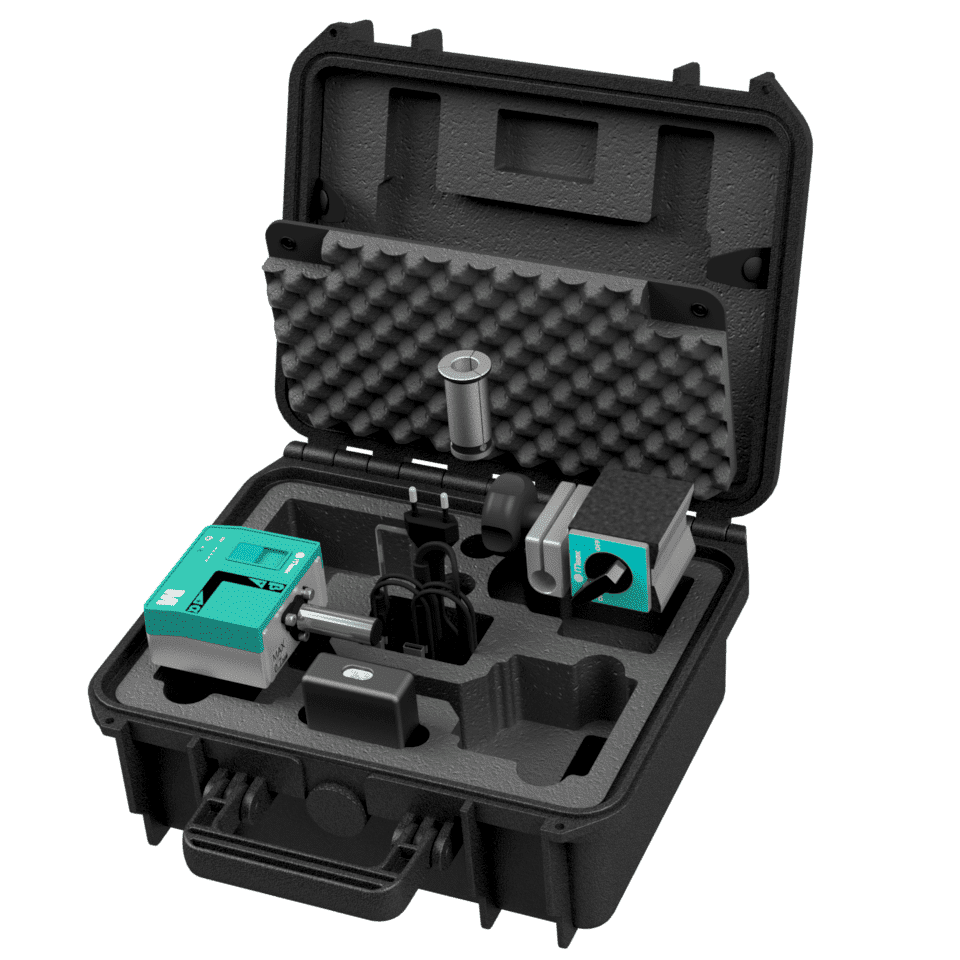

A unique feature of Meax Level is that combines a wide measurement range (±100 mm/m) with high accuracy (± 0,005/m) which is constant in its entire measuring range. This feature allows the MEAX Level sensor to be mounted on the surface using a magnetic base, in tool holders using a 16mm shaft holder, or to be mounted on customized fixtures which further increases the flexibility of the Meax Level Single system.

Meax® Level Single

Meax® Level is a unique 2-axis high precision inclination sensor with a large measuring range (± 100 mm/m) with the same accuracy (± 5 µm/m).

The MEAX Level Single uses one 2 axes-sensor for different measurement tasks when checking the geometry status of machine tools. It uses the readings from the 2-axes level sensor and connects to any mobile device which displays the measuring results in the Meax Level App.

With Meax Level Single it is possible to measure an object’s inclination towards gravity (leveling) or to measure an object’s relative angular deviation (roll/pitch) during machine axes movement. The sensor can also be used to monitor any angular movements over time.

A unique feature of Meax Level is that combines a wide measurement range (±100 mm/m) with high accuracy (± 0,005/m) which is constant in its entire measuring range. This feature allows the MEAX Level sensor to be mounted on the surface using a magnetic base, in tool holders using a 16mm shaft holder, or to be mounted on customized fixtures which further increases the flexibility of the Meax Level Single system.

Beskrivning

The 2-axis level sensor

The future of machine tool leveling measurement is here. MEAX Level has brought together new technology that generates accuracy down to 0,005 mm/m with a user interface in smartphones and tablets. Within five minutes, MEAX Level will enable you to determine whether the machine is in level and is receiving data concerning roll/pitch in the machine’s movement. Thanks to a wireless connection to the smartphone or tablet, MEAX Level reads two angles in the same measurement.

Logical interface

MEAX Level is equipped with Bluetooth, which you use to connect to your mobile unit (iOS or Android). This is easily achieved by the user-friendly MEAX Level App. It displays the angle deviation down to a resolution of 0,001 mm/m. The results are saved on your device and can be shared in any way you wish from your file handling system, through e-mail, etc

Industrial use

- The level sensors come fitted with batteries sufficient for 12 hours of continuous operation.

- Each sensor includes a battery indicator which displays the battery status without activating the sensors or tablet.

- The design and color are customized to be easily seen in an industrial environment.

- MEAX Level is also IP65-classed, giving a significant level of protection against liquids and dust.

Ladda ner appen