Falcon

The ultimate portable vibration data collector and analyzer

Falcon

FALCON is an innovative tool for vibration measurement and analysis that puts condition-based maintenance within the grasp of all users.

With a wide range of optional features available, the FALCON can be configured to perform balancing, run up/ coast-down, frequency analysis and more.

– Wireless vibration analysis

– Graphical, touch screen interface

– Three-axis wireless sensor

– Ideal for route-based maintenance

– Fast vibration analysis: each bearing takes an average of 8 seconds to measure!

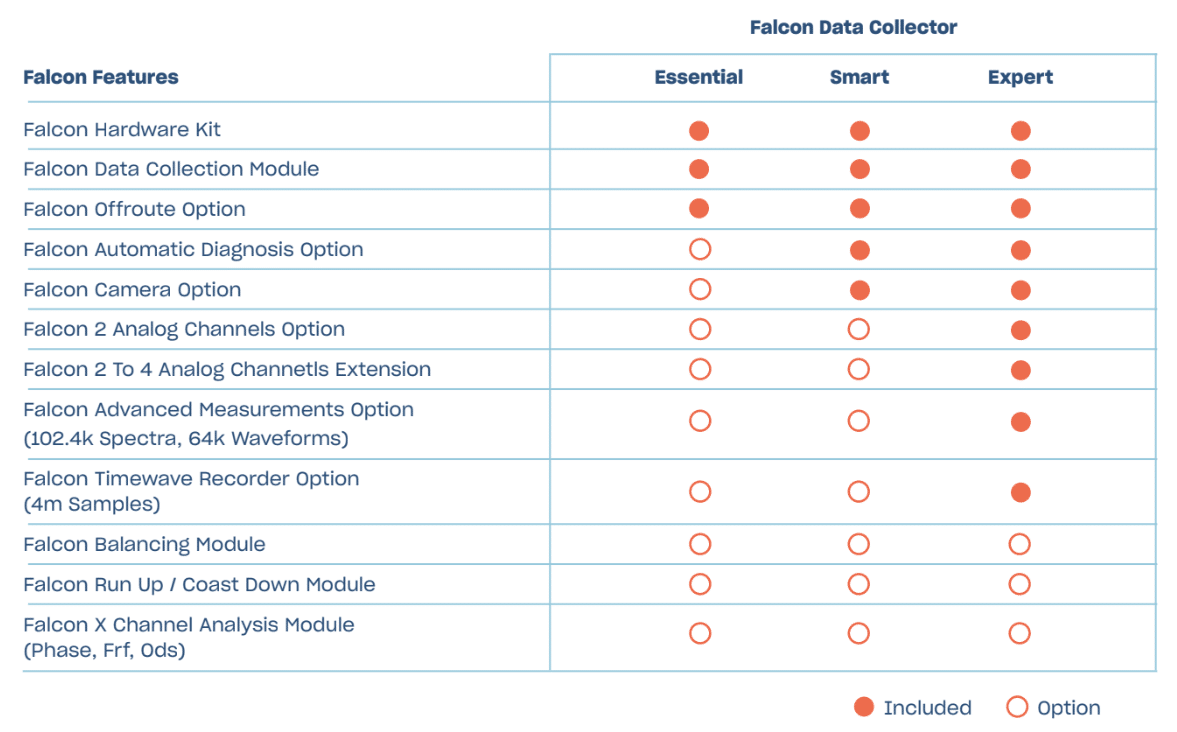

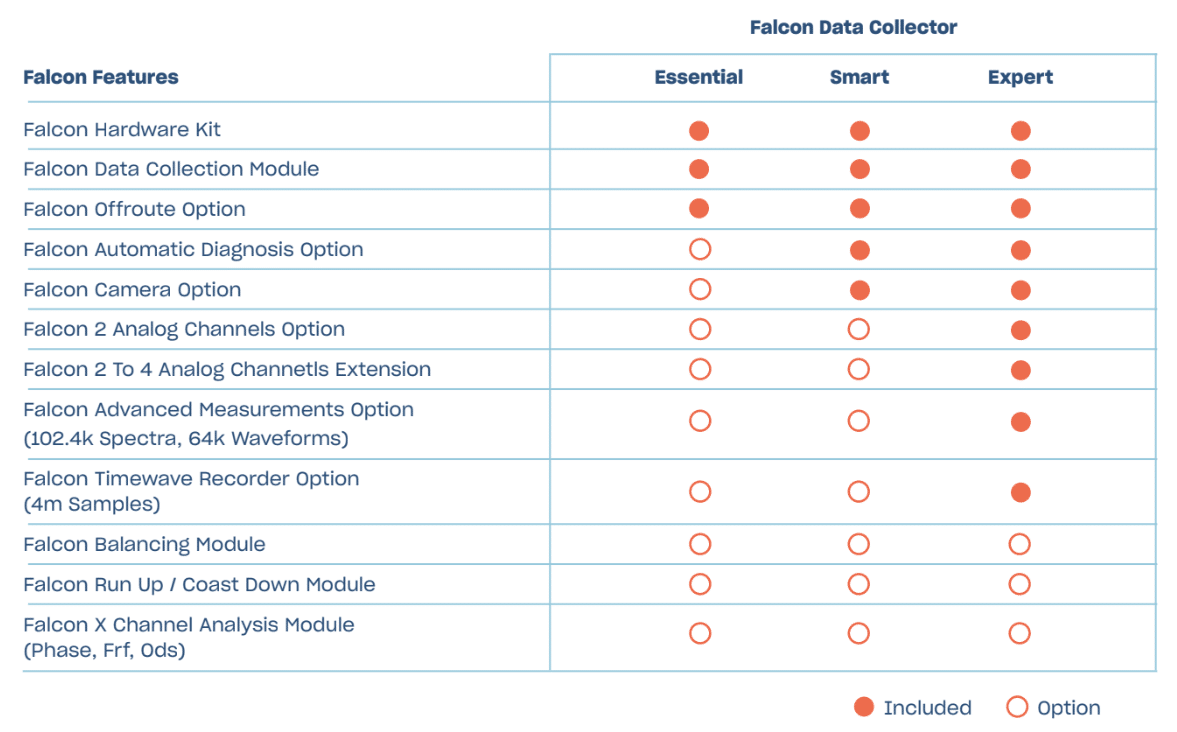

– Available in four configurations: Essential, Smart, Expert and Ultimate (full options)

– Built-in accessories: stroboscope, pyrometer, camera, QR code reader, and audio comment recorder.

– Acquisition of multi-channel time signals up to 80s at 51.2kHz (4 Mega samples)

FALCON is also available in EX versions.

FALCON is also available in EX versions.

Falcon

FALCON is an innovative tool for vibration measurement and analysis that puts condition-based maintenance within the grasp of all users.

With a wide range of optional features available, the FALCON can be configured to perform balancing, run up/ coast-down, frequency analysis and more.

– Wireless vibration analysis

– Graphical, touch screen interface

– Three-axis wireless sensor

– Ideal for route-based maintenance

– Fast vibration analysis: each bearing takes an average of 8 seconds to measure!

– Available in four configurations: Essential, Smart, Expert and Ultimate (full options)

– Built-in accessories: stroboscope, pyrometer, camera, QR code reader, and audio comment recorder.

– Acquisition of multi-channel time signals up to 80s at 51.2kHz (4 Mega samples)

FALCON is also available in EX versions.

FALCON is also available in EX versions.

Beskrivning

All-in-one

- three-axis wireless sensor, taking simultaneous vibration measurements in all directions

- built-in strobe light for rotation speed measurement

- built-in laser pyrometer for bearing temperature measurement

- built-in camera for easy machine identification, sensor positioning, and report illustration

- embedded Accurex™ automatic diagnostic

- 4 analog channels for synchronous measurement, in addition to the trigger input

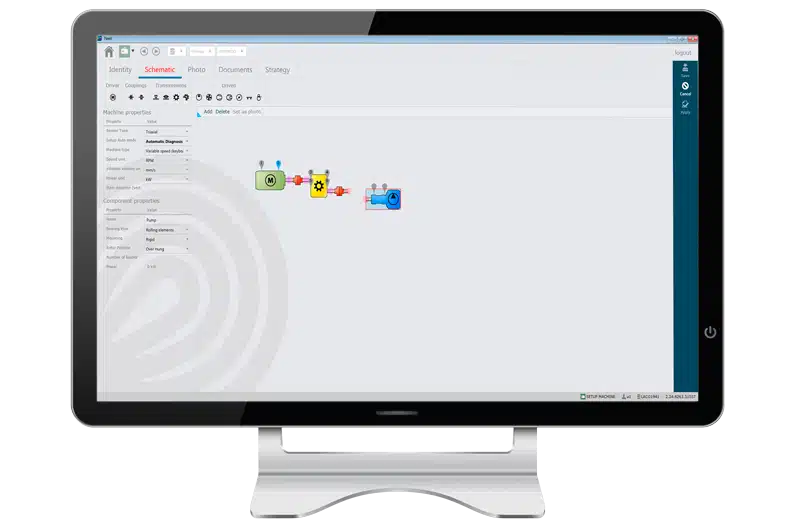

Accurex™ automatic diagnostic

FALCON allows making immediate use of the benefits of condition-based maintenance: the Accurex™ automatic diagnostic works instantly based on the first measurement. Faults detected are available right in front of the machine enabling interaction with the user (bearing lubrication, temperature control…) and optimization of the maintenance process.

Based on the ISO 10816 standard and Acoem 30+ years of experience, FALCON’s built-in automatic diagnostic module provides unbeatably relevant and reliable results. Identified machines are presented with an overall risk assessment indicator to help the user prioritize his analysis of critical machines. Every fault detected is displayed with its severity, location on the machine, and confidence level (patent pending).

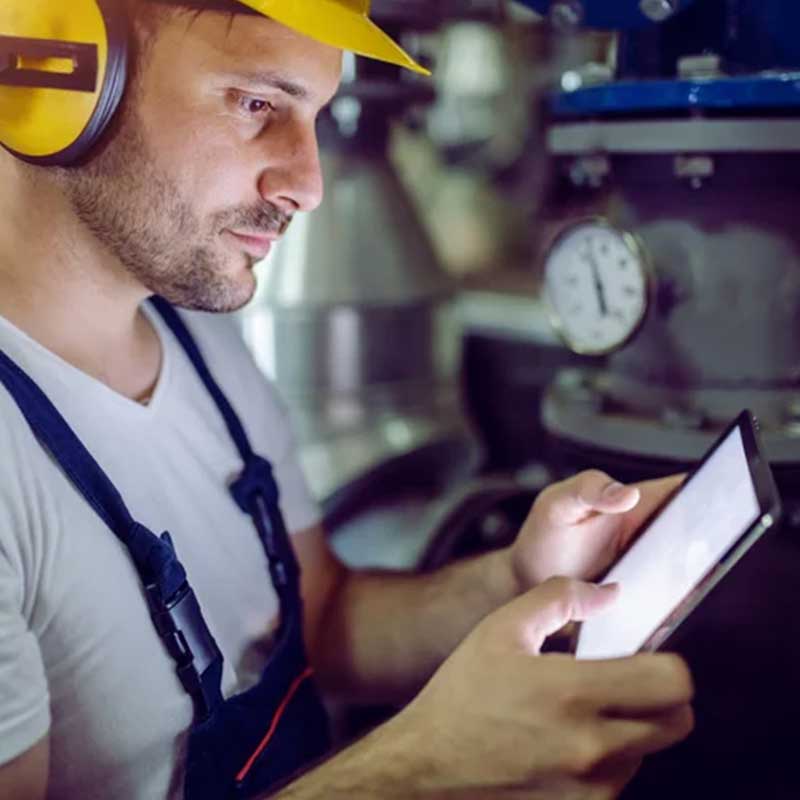

Measurement productivity

The wireless three-axis sensor and real-time processing capabilities cut times of vibration measurements: 8 seconds per bearing typical for measuring all X Y and Z directions with the highest quality set of vibration data. With the use of pictures, the machine identification among a route has never been so easy. The user can navigates on FALCON’s large colorful touchscreen from the top view of the plant down to the sensor position picture on the machine.

FALCON reduces the time and costs needed for on-site intervention to the absolute minimum. At the scale of a plant, FALCON stands out.

Reliable by design

FALCON was designed for uncompromised industrial use in the harshest settings:

- ATEX Zone 2

- IP65

- Withstands a 1.2-meter drop.

FALCON comes with a large color touch screen, which can even be used with safety gloves, a rubber grip for better handling, and anti-shock resistance. The wireless accelerometer eliminates safety concerns with cables and rotating machinery, and within a range of 10 to 20m between the wireless sensor and the unit, measurements can be performed outside protective barriers or with closed doors. The user is less exposed to heat, smoke, noise, or other potentially harmful environments.

Ytterligare information

| Configuration | FALCON Essential, FALCON Essential EX, FALCON Smart, FALCON Smart EX, FALCON Expert, FALCON Expert EX, FALCON Ultimate, FALCON Ultimate EX |

|---|